Our expertise

Plastics welding Thermoplastics

High-frequency welding is a joining technique applied to thermoplastic materials, using mechanical pressure combined with a 27.12 MHz electromagnetic wave. This tough, watertight welding technique sets the molecules of thermoplastic materials in motion, allowing them to be heated to melting point, without necessarily adding temperature to the electrodes.

The benefits of HF :

- Fast, even heating of materials without damage

- Strong, uniform and durable welds

- Air-, water- and gas-tight welds

- Multi-layer welding possible

- Few fumes emitted during soldering (unlike using glue)

MATRELEC’s know-how is based on strong technical expertise and perfect control of our HF generators, developed and manufactured in-house. This expertise enables us to understand and manage each welding application with relevance, and to guide you in choosing the most appropriate solution in terms of machine and tooling.

Production traceability

Matrelec has developed management and control solutions for its machines, enabling traceability of each weld in the case of sensitive products or those requiring precise tracking. Our machines can manage different recipes, the history of welds and their behavior.

The history, which is permanently saved, can be analyzed at any time. Visualization of welding curves enables technicians to improve weld quality or optimize production rates.

This also enables us to mark each product in real time in the production cycle, for perfect, indelible traceability.

Mastering robotics

We are committed to optimizing your production, whatever your market.

The integration of robots for loading and unloading operations, for example, offers significant productivity gains.

All our solutions are the fruit of years of experience and know-how.

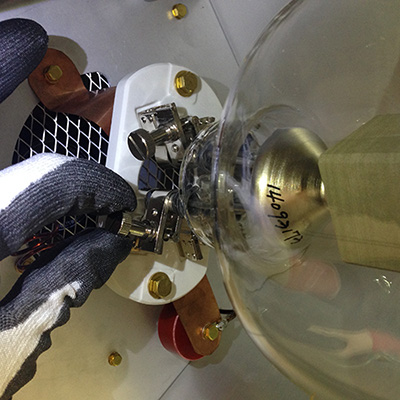

The HF laboratory

Our fully-equipped lab is equipped with high-frequency and thermal welding presses, test benches, measuring equipment and microscopes.

Come and test your materials on our welding machines. Measure the quality of welds, make samples using your own materials for testing.

- PVC WELDING

- PU WELDING

- EVA WELDING

- WELDING PETG

- WELDING ON COATED TEXTILES

Our technical lab opens up new perspectives in :

- Discover the fundamentals of high frequency and its applications

- Product development and prototyping

- Testing the welding quality of your materials (strength, thickness, tightness, etc.)

Designed to accommodate our customers and partners, the lab enables you to carry out all your welding tests on PVC, PU, EVA, PETG and coated fabrics. Equipped with high-frequency and thermal welding presses, a tensile test bench, measuring equipment and a digital microscope, Matrelec’s highly qualified technicians can provide you with support and expertise in product and process development.

This lab is also dedicated to our pre-project unit, which carries out all the tests required to ensure that your project runs smoothly.

Measuring instruments :

- Mecmesin Traction Bench

- Nikon digital microscope

- TAMeasuring equipment

Presses at your disposal :

- Press CCM 30 PA

- Press Q126 T2

HF training

High-frequency training is essential in the world of work. It enables everyone to maintain a high level of skill and productivity. Take advantage of our expertise in high-frequency technology to learn more about how to work with it.

Matrelec offers specific high-frequency training courses for your technicians, production operators and design offices. Our production operator training courses will enable your teams to acquire the basics of high frequency, enabling them to optimize settings and improve your production.

Our maintenance technician training courses will enable your teams to acquire the basics of high-frequency operation and methodical troubleshooting.

Contact us

If you have any questions about our machines, would like a quotation or would like to discuss any other matter, please contact us using the form below.