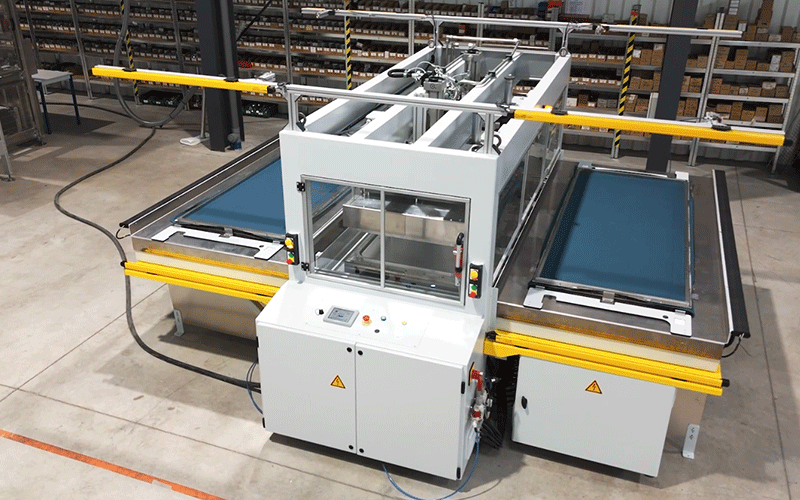

Thermal presses

Press plate” thermal welding

Complementing our range of high-frequency machines, all our rotary and transfer table machines are equipped with “Press Plate” thermal welding technology, an ideal solution for industrial applications requiring large, robust and uniform welds on materials that could not be processed with high-frequency, or as a complement to high-frequency for rigid materials, for example. This process uses a heating plate in direct contact with the material, enabling welds at temperatures of up to 200°C.

The heat-sealing machines we offer are equipped with pneumatic cylinders for thrusts of 1.8 to 3 tons to ensure weld strength. The welding zone can be up to 900×1500 mm for welding large products in a single operation.

The advantages of thermal welding include high production rates, ease of use and versatility compared with other technologies. Inexpensive tools and easy machine maintenance are also two advantages of this technology.