HF Technology

Introduction

High-frequency heating is an electrothermal heating process based on high-frequency electrical oscillations produced by oscillating circuits associated with thermionic electron tubes. There are two types of HF heating:

- Induction heating using frequencies from 200 KHz to 5 MHz is reserved for heating conductive materials.

- Dielectric loss heating (or capacitive heating) using a frequency of 5 MHZ to 100 MHz for heating electrically insulating materials.

Dielectric loss heating is based on the heat losses that occur in insulating bodies subjected to a high-frequency alternating electric field.

Although SIEMENS foresaw this technology as early as 1864, it was not implemented until 1935, following the work of Messrs. Dufour and Leduc, who used it to process rubber. From Lord onwards, the technology was used for a variety of applications: heating glass, drying paper, textiles, tobacco, wood, etc…

The main feature of this process is the uniform temperature within the heated mass, enabling rapid temperature rise without damaging the material.

As the heating effect is proportional to the resistance of the exciter field, very high frequencies are used.

In industry, technology began to play an important role with the advent of PVC.

To produce a weld, the material is placed between two electrodes (usually a tool and a counter-tool), which are subjected to a sinusoidal alternating voltage that causes the material to heat up.

In the industrial sector, the law requires the use of the three frequencies allocated to industry, namely :

- 13.56 MHz + 0.05

- 27.12 MHz + 0.6%: the one we use on our generators for high-frequency welding

- 40.68 MHz + 0.05

How dielectric loss welding works

High-frequency (HF) welding uses high-frequency electromagnetic energy (27.12 MHz) to generate heat in materials. The material to be welded must be capable of converting the alternating electric field into heat.

Materials are subjected to an alternating HF electric field. As the current passes through the material, it loses part of its energy, which spreads through the material (these are the dielectric or heat losses).

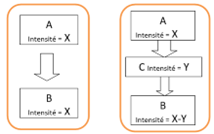

- If there is no material, the electric current passes through the field without losses: its intensity is the same at the beginning (A) and at the end (B) (figure 0.1).

- If a dielectric material is located in the field (C), part of the electric current will dissipate in the material: its intensity will be higher before passing through the material (A), and lower afterwards (B) (figure 0.2).

During the dielectric loss process, part of the energy is absorbed by the material and is not released, but is transformed into heat.

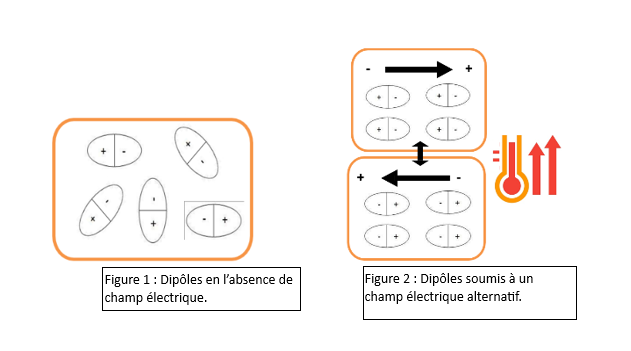

This process is called bipolar polarization, which occurs at the molecular level in materials composed of bipolar molecules.

Non-polar molecules in an electric field displace electrons so that their positive and negative charge centers no longer coincide. The phenomenon is instantaneous and does not involve the generation of DC heat. The dipolar polarization used in HF welding, however, is not instantaneous. In the presence of an alternating electric field, the orientation of the dipoles is also “alternating”: they change position as the current varies (figure 2), 27 million times per second (27.12 MHz). As the dipoles attempt to align themselves with the rapidly alternating electric field, the orientation becomes out of phase. Imperfect alignment causes internal molecular friction and leads to heat generation. The delay between changes in electric field direction and changes in dipole polarization is illustrated in Fig. 3.

The principle is the same as that used to heat food in the microwave: the microwave phenomenon agitates the water molecules, causing them to heat up, thereby heating the food.

An HF welding press consists of an upper, movable part, and a lower, fixed part, called the counter tool. The movable part holds the welding head, which supports the tools commonly known as welding electrodes or welding jigs.

The head is usually connected to the HF generator, but sometimes the lower plate is connected, depending on the application. If the upper plate is connected to HF, the lower plate will be connected to ground, and vice versa. The tooling defines the shape and dimensions of the weld.

The materials to be welded are placed between the electrode and the marble, and the press applies pressure to the weld zone.

HF power is then applied for a preset time, called the weld time. Once the weld time has elapsed, pressure continues to be applied to the materials until the weld solidifies. This is called the cooling time. The press then opens, releasing the welded assembly.

HF welding is normally only used for joining thin, flexible films and materials. This is because a sufficiently powerful electric field is difficult to generate, and material fusion more difficult, if the gap between the electrode and the marble is greater than 3 mm.

Advantages and disadvantages

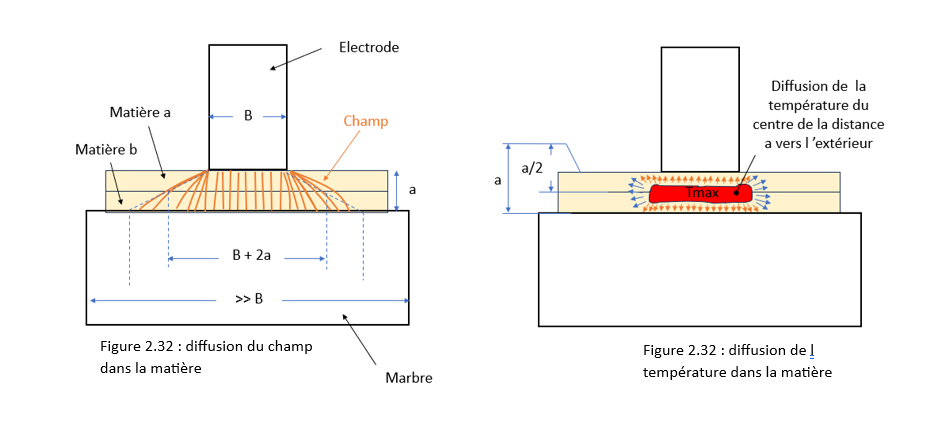

HF welding uses a process that requires only electricity and compressed air. The molecular excitation process avoids the release of noxious gases or the use of solvent or adhesive for welding, which minimizes the risk of contamination and facilitates the recyclability of welded parts. In addition, cycle times are relatively short (up to 20 strokes per minute in automated processes). The molecular excitation process heats the material to be welded from the inside out (fig 2.32), thus avoiding “bludgeoning” the material and providing the most self-generating weld of all plastic welding processes.

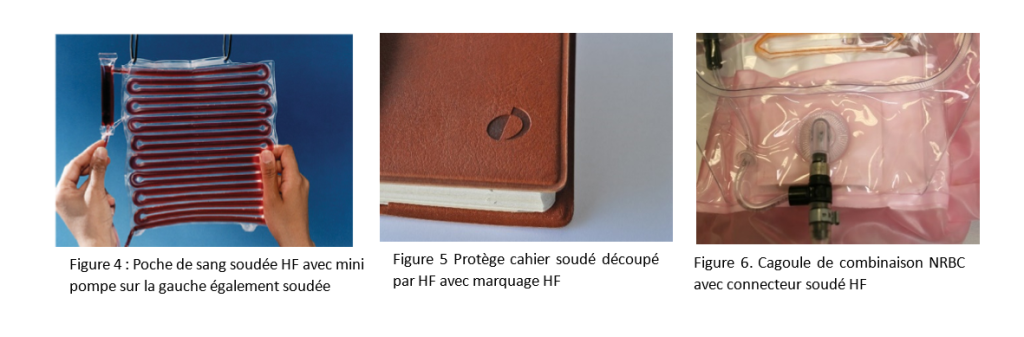

HF welding presses can also be used for cutting welding (fig 5). Electrodes can be made to allow the welded part to be removed from the base material, the remaining material becoming what is known as “waste”, without the need for a secondary cutting operation, but this cut-welding operation is only feasible on film and not on coated fabric, which requires mechanical cutting and much more pressure than conventional welding pressures.

Marks (fig 5) and folds can also be created on a product without damaging the material. It is also possible to weld accessories such as valves (fig 6 and 7) or tubes at any point on a product without welding the underlying materials, using insulators. Finally, for certain applications, high-frequency welding can be used for marking, embossing or molding a shape.

The major drawback of HF welding is that it is only suitable for materials with a polar molecular structure. Non-polar materials can be welded, but require the addition of polar material between thicknesses, as in the case of complex films comprising several different materials (e.g. PE/EVOH/PE). In some cases, we speak of filler strips, which react at the wrong frequency and enable heating.

Fields of application

HF welding is commonly used to seal thin sheets and films of plasticized PVC for stationery products, such as pocket folders, checkbook pockets, credit card holders and book covers. Another major market is for inflatable products (fig 7), such as beach balls, inflatable mattresses, life jackets, air bags and inflatable dinghies.

Other applications include medical items, such as gastric balloons, blood bags (Fig. 4), disposable nuclear garments such as CBRN suits (Fig. 6), orthopedic products, inflatable structures, blood pressure cuffs, inflatable beds and cushions (Fig. 6). HF welding is also used for blister packs and other types of packaging.

Finally, HF welding is widely used in the tarpaulin industry for welding truck tarpaulins, water tanks (fig 8), swimming pool covers, liner, pergolas and shade cloths.

Many of our products are high-frequency welded, and you’ll find examples in the industry section of our website, here.