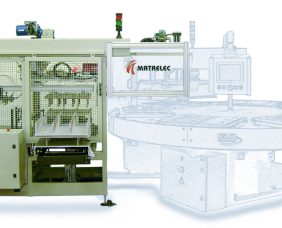

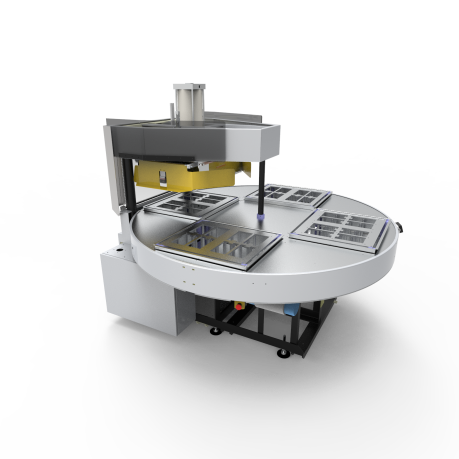

High-frequency rotary table welding press

Optimize your production

Rotary tables are perfectly suited to high production rates and/or the production of elaborate products requiring multiple operations.

Simultaneously, several operators alternate between welding operations and product placement, thus optimizing production. Automation options also help to increase output.

For more complex products, each station can be dedicated to a different task, with the T series equipped with several welding heads.

The benefits

- Multiple welding heads for complex products

- Up to 6 workstations: multiple operators can work on the machine

- Possibility of automated sheet or carton depositing, inkjet product marking, blister stripping”.

Technical specifications

Max. HF power at electrode: 10 to 15 kW

Maximum weld area: 250 to 375 cm².

Maximum pressure: 1.8T to 5T

Headroom: 480 mm

Force type: Hydraulic / pneumatic / electric

Power supply: 3 phases + Neutral 400V 50 Hz

Marble dimensions: 3 phases + Neutral 400V 50 Hz

Number of positions: 4 to 6

Number of automatable stations: 5

Hot marking of products Air conditioning of tooling 25 to 50°C

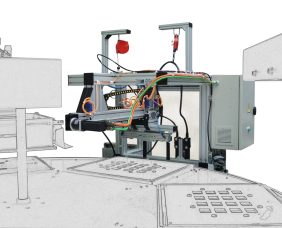

Manipulator for automatic size removal

Automatic stripper

Laser marking of products

Vision control

Thickness control

Applications