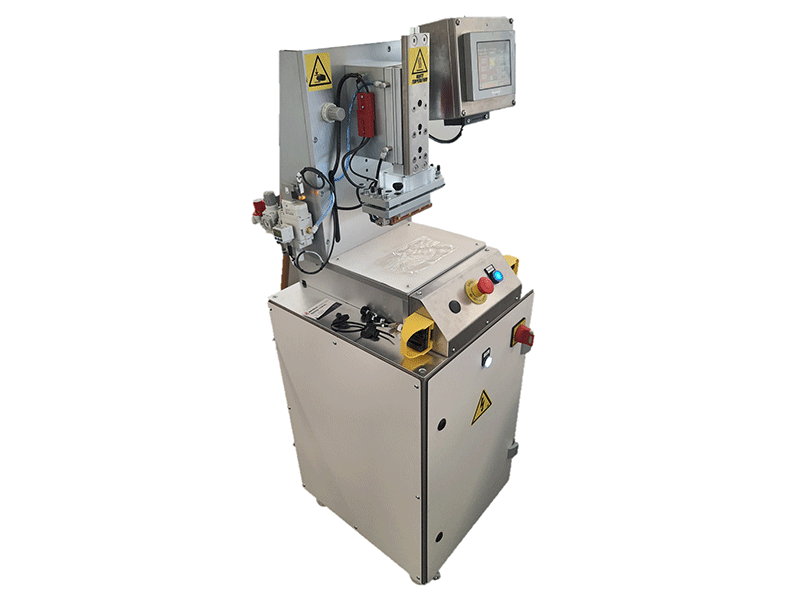

Impulse presses

Impulse welding

In addition to our range of high-frequency welding presses, we also offer impulse welding presses, an advanced and precise thermal technology for sealing plastics. This process is particularly well-suited to high-demand sectors (food, medical, cosmetics, automotive), and excels in applications requiring sensitive welds on thin materials, or for welding recycled or mono-material materials.

The pulse-welding system operates via controlled electrical pulses that enable heating at the precise moment of welding, thus minimizing thermal stress on materials. This technology enables high cycle rates, up to 120 cycles per minute, and reduces the risk of burns and wear, for greater energy efficiency. In addition to this solution, which can be adapted to all our machines, we offer a range of machines dedicated exclusively to impulse welding.

This technology also enables temperature management as close as possible to the material, with the tool acting as a temperature sensor. This welding process will be effective on thin materials and on materials that cannot be welded at high frequency.