Industrial triodes

Frequently asked questions about triodes

What is a triode?

Born under the name of audion in 1906, the triode is a vacuum lamp (electron tube) made up of three different electrodes: the emitting cathode, the intermediate grid and the receiving anode.

- A hot electron emitter, the cathode consists of an incandescent filament or a plate heated by such a filament. This temperature rise gives electrons the energy they need to free themselves from the support and form an electron cloud around the cathode.

- Applying an electrical potential difference of between the cathode and the anode accelerates the movement of electrons towards the anode. This results in a current of a few milliamps in the electronic circuit.

- By interposing a grid between the two electrodes, the potential can be modulated to restrict or promote the passage of electrons. A small variation in electrical potential on the grid results in a large variation in the current collected by the anode, according to the principle of amplification.

The triode works like a switch on the ” all or nothing ” principle, and enables significant amplification of the electronic signal without generating distortion effects.

What types of triodes are used in industry?

What types of machines use industrial triodes?

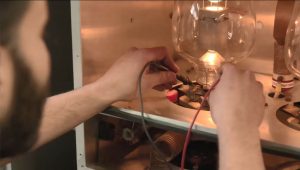

What makes up a high-frequency generator?

On an HF welding press, the generator is responsible for transforming electrical energy into high-frequency waves to power the electrodes. Incorporated into the machine frame, it is made up of the following components:

- a electron tube or high-frequency triode ,

- a triode cooling circuit,

- a current galvanometer for the anode,

- an anode circuit breaker.

- a water-cooled or forced-air-cooled heat sink

- an oscillator for quarter-wave HF energy transfer,

- a motorized variable capacitor for high-frequency adjustment,

- automatic HF power regulation at 27.12 MHz,

- an anti-flash device electronically sensitive thyristor,

- a shielded high-frequency line.

How do I make the triode last on an HF welding machine?

For high-frequency soldering presses, the electronic tubes are among the wear parts with the highest renewal or replacement costs. It is therefore essential to maximize the precautions taken when using triodes, in order to optimize their potential lifespan through a few common-sense measures:

- Observe a minimum warm-up phase of ten minutes at the start-up of the welding machine before starting product assembly operations.

- After completing a sequence of welding operations, it’s best to let the diode cool down for about a quarter of an hour before shutting down the press.

- Ensure that filters are cleaned on a regular basis, with the frequency depending on the level of dust in the production environment (weekly, fortnightly, monthly, etc.).