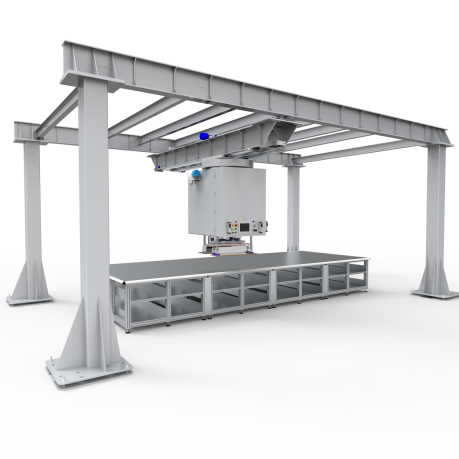

Overhead press

Automated welding for very large products

GS-type overhead presses can be used to weld large, bulky products. They can be integrated on an existing table, have a welding table of the required size, or work at floor level. For example, by moving the head, you can place and weld accessories at the required position on a large product, without having to move it; the head will automatically or manually position itself on these accessories.

The benefits

- Easy two-man operation

- Easy material handling thanks to the absence of swan necks

- Good visibility of the welding zone thanks to the available headroom

- Custom marble dimensions

- Rapid tooling attachment via T-slot.

- Several power levels for use with small tools

- Consistent weld quality and traceability thanks to automatic tuning

- Flying tools can be used over the entire work area

- Save welding parameters as recipes for quick series changes.

- Automatic 3-axis movement

Technical specifications

Gooseneck: Infinite

Dimensions L x W x H: 1560 x 1400 x 1700 (excluding structure and lower marble)

Weight: 800 kG (excluding structure and lower marble)

Max. HF power at electrode: 15 kW

Maximum weld area: 500 cm².

Maximum pressure: 1.8 T

Available headroom: 280

Force type: pneumatic

Power supply: 3 phases + Neutral 400 V 50 Hz

Applications