Carding

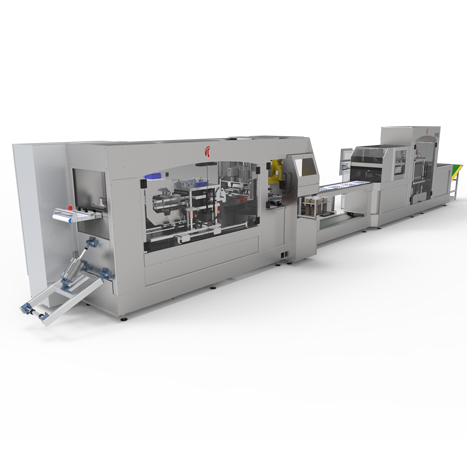

AUTOMATIC LINE FOR CREATING CARDING PACKAGING

Economic production and a larger communication area

Carding machines are perfectly suited for blister pack welding on coated paperboards

for high volume production.

Equipped with a thermoforming station, high-frequency and thermal heat sealing,

automatic supply of paperboards and plates in a 320 x 475 mm format, these

machines use a spool to produce packaging at a rate of about 50 products per minute,

depending the format.

The various options available, such as automatic supply, tool temperature

conditioning, dual storage or the preheating furnace, can increase your productivity

even further.

ADVANTAGES

- Quick tool or format change (<30 minutes)

- Independent management and configuration of each station

- Data management and simplified process display

- Automatic supply of paperboard and blister filling by several operators

- Double spool holder

- Compact size of 400 x 250 or 500 x 350 tools</li<

| Format | 100 x 200 / 400 x 250 / 500 x 350 mm |

|---|---|

| Dimensions L x l x h | 9,5 x 2,5 m |

| HF max power at the electrode | 6 à 15 KW |

| Maximum weld area | 375 cm² |

| Maximum pressure | 1,8 T |

| Feed |

Triphasé 400V 50 Hz |

| Automating |

Air conditioning and temperature control Oven for maintaining the temperature of tools Double cardboard storeAutomatic filling of hulls Automatic filling of hulls |

| Type of force | Pneumatic |